MinimizingDowntimeof Machineries

Prolonged machine downtime during breakdown leads to low profitability.

PROBLEMS WE SOLVE

It takes time to dispatch mechanics to the site

Prioritization of sites to be addressed. Efficient allocation considering mechanics' skills and standby locations.

Repairs take a long time

Proper reporting of the breakdown status. Appropriate work instructions for the breakdowns. Arranging tools and parts correctly.

Fundamental repairs are not made, causing recurring breakdowns

Work instructions managed by the managers. PDCA cycle driven by data analysis of recurrence rates, repair details, and other data.

FEATURES

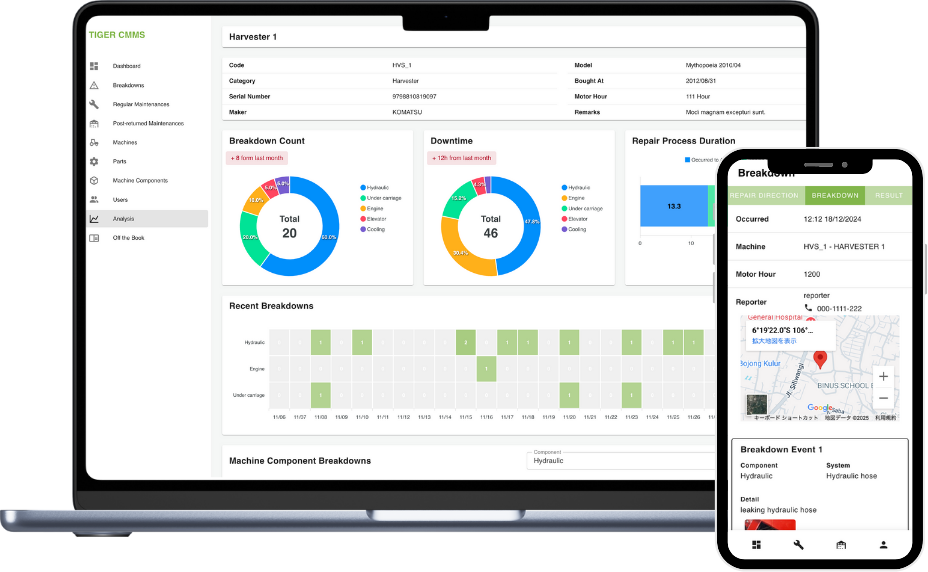

Repair & Maintenance System

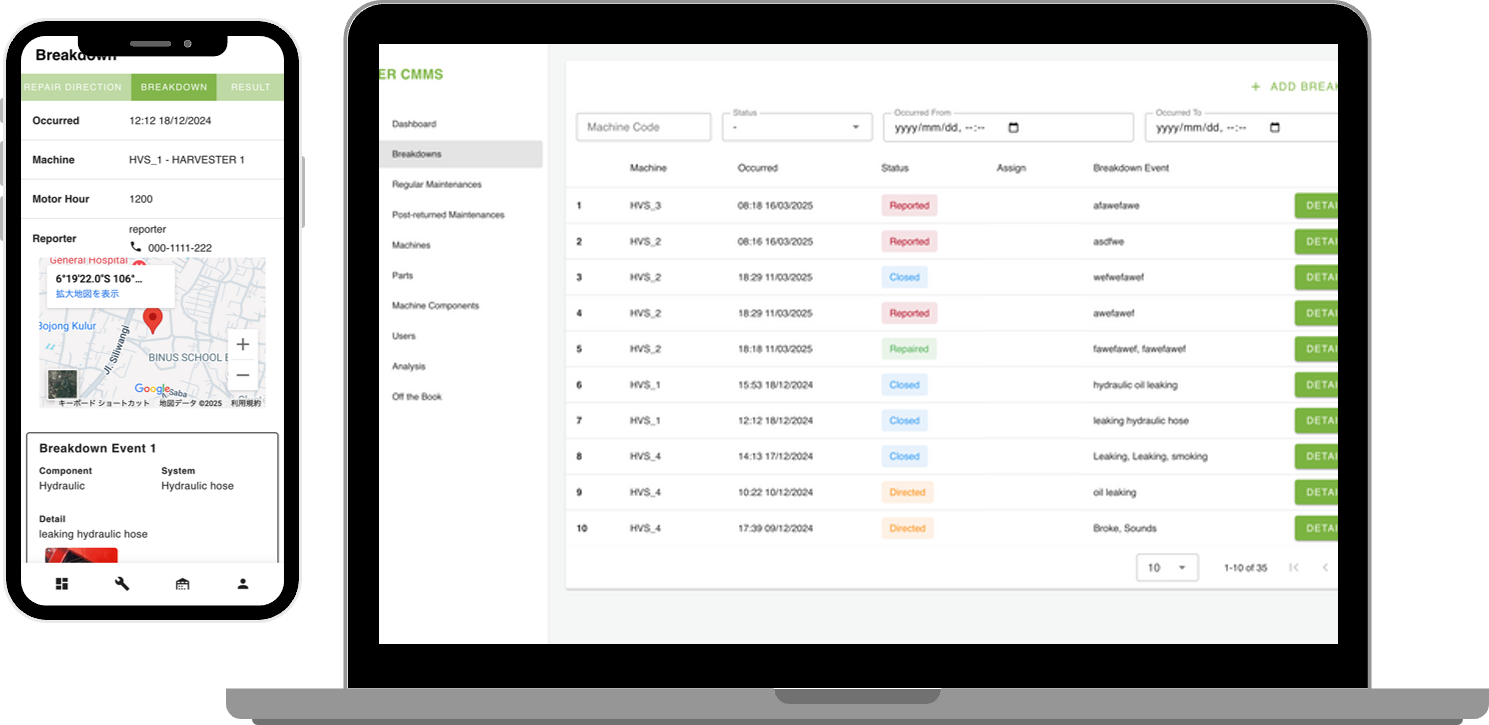

Repair

- •Smart Breakdown Reporting (AI-assisted + media attachments)

- •Repair Queue Management (Overview of pending and completed repairs)

- •Mechanic Assignment (Based on location, schedule, and skill fit)

- •Repair Instructions (AI-assisted with work content, target time, and parts/tool preparation)

- •Repair Review & History Tracking

Maintenance

- •PM Planning (AI-assisted with mechanic assignment)

- •PM Queue Management (Schedule and task tracking for planned maintenance)

- •PM Review & History Tracking

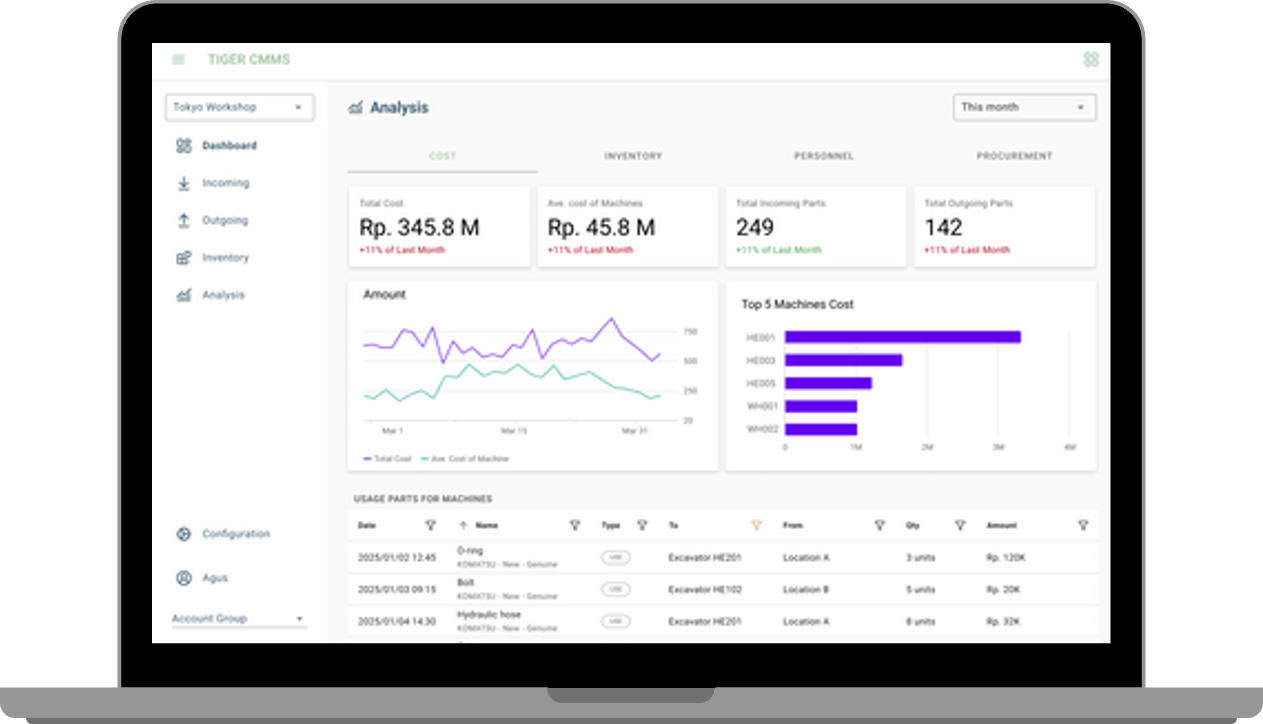

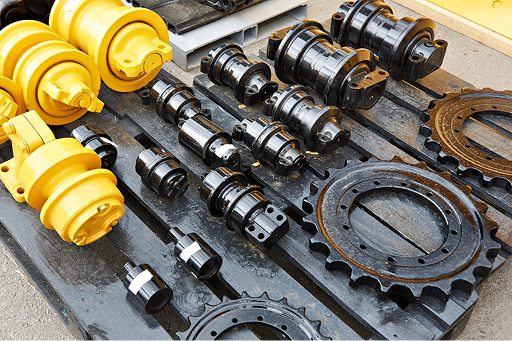

Parts Management System

Off-the-Book Parts Management

- •Track Incoming, Outgoing, and Usage of Parts

- •On- and Off-the-Book Inventory Position Management via ERP Integration

Part Usage Analysis

- •Inventory Position per Part

- •Safety Inventory Calculation and Identification of Parts for Cost Reduction

- •Track Parts Usage for Each Machine and Mechanic, and Link It to Associated Costs

Compliance

- •Prevention and Monitoring of Unauthorized Part Removal and Usage

- •Return Management for Unused and Replaced Parts from Repairs/Maintenance

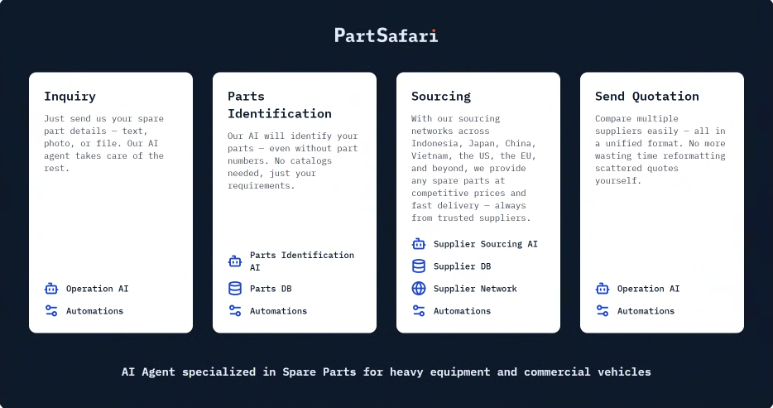

Trigger-Based Parts Proposal

- •Automatic Parts Quotation from PT Three Tiger Indonesia upon Stock-Out Detection

- •→ Minimized Lead Time for Parts Procurement via PartSafari

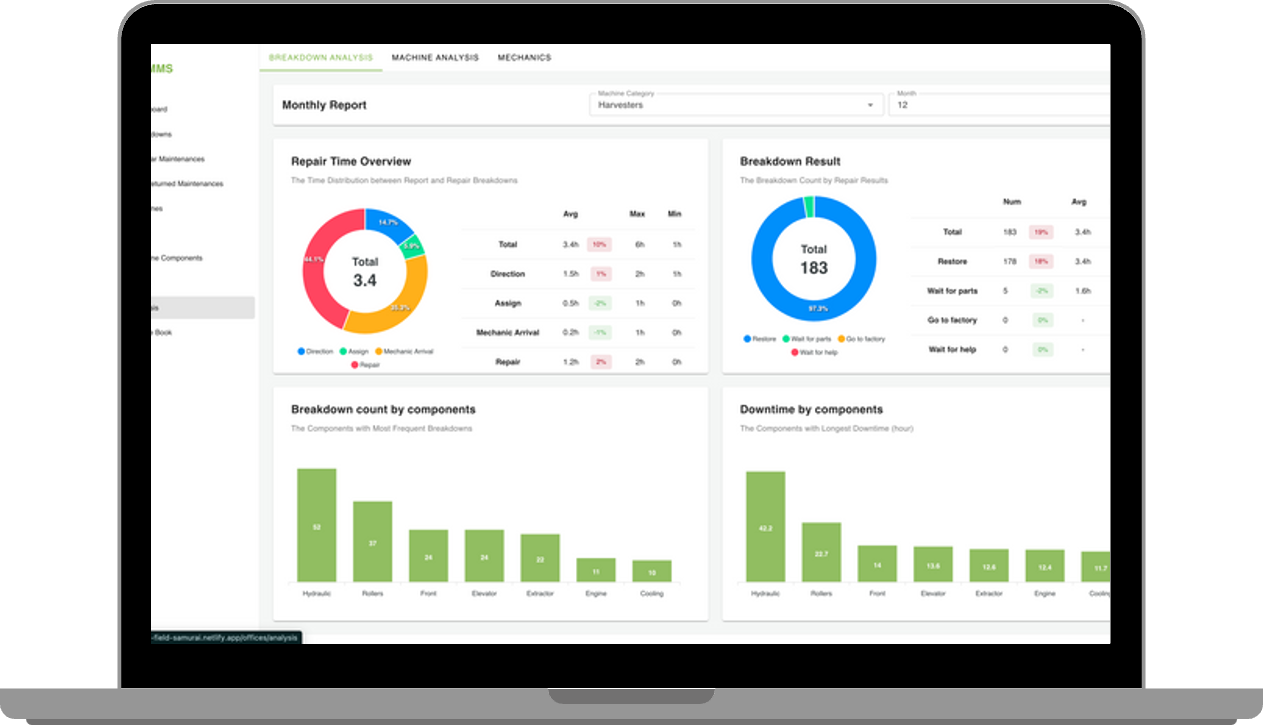

Data Analytics Dashboard

Machine Performance

- •Track Uptime, Utilization, Hour Meter, Kilo Meter

Maintenance and Repair Performance

- •Monitoring of KPIs related to downtime

- •Machine Ranking by Downtime – Identify machines with the highest cumulative downtime

- •Downtime Breakdown by Cause – Identify top contributors to total downtime by cause

- •Drill-Down from Downtime to Individual Maintenance/Repair Records – Navigate directly to detailed maintenance and repair history from downtime data

Mechanics' Performance

- •Monitoring of KPIs related to mechanics

- •Performance Analysis per Mechanic

- •Identify Strengths and Weaknesses of each Mechanic

- •Use analysis results to inform training programs and hiring strategies

ABOUT US

Innovate Asia's Construction Equipment Aftermarket

Three Tiger Inc. is a Japanese technology startup revolutionizing Asia's construction equipment aftermarket. Our goal is to enhance productivity and profitability for industry stakeholders, including equipment owners, repair shops, and suppliers.

Our team has more than 10 years of experience in construction equipment industry and digital industry.

EXPLORE OUR OTHER SERVICES

Used Equipment & Parts Sales

We provide high-quality, cost-effective new parts for construction and mining machinery. With our supplier network in Japan, Thailand, and Indonesia, we also source and deliver used machines, components, and parts for various models. Our comprehensive service includes logistics and import/export.

PartSafari

Parts Procurement, Simplified. Our AI-driven platform identifies the right parts in seconds, ZERO stress for your purchasing team. for Heavy Equipment and Commercial Vehicles